Factory Automation

Engineering Services

Factory automation engineers (mechanical, electrical, and control design engineers) from our company and partner companies utilize simulation software to support study, design, verification, and evaluation activities for automation (automation and labor saving) of production activities in a digital environment.

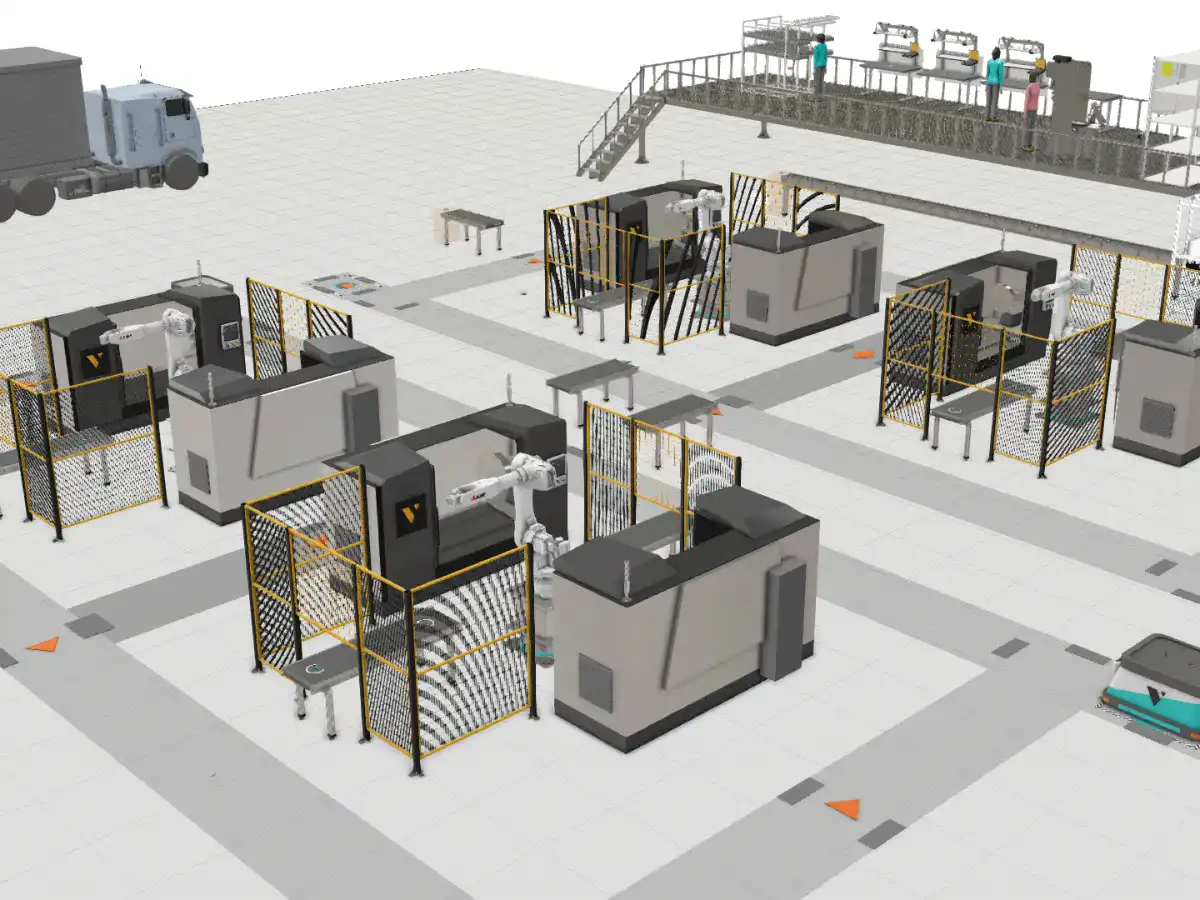

Digital Twin Engineering

Visual Utilizing Visual Components' simulation software, we support machine conception and design quality verification through 3D simulation. We also provide control program verification in a digital environment to support labor-saving machine investment studies and manufacturing process evaluations.

- Point

Conceptual study by 3D simulation.

Quality check of 3D design.

Manufacturing Process Efficiency Assessment.

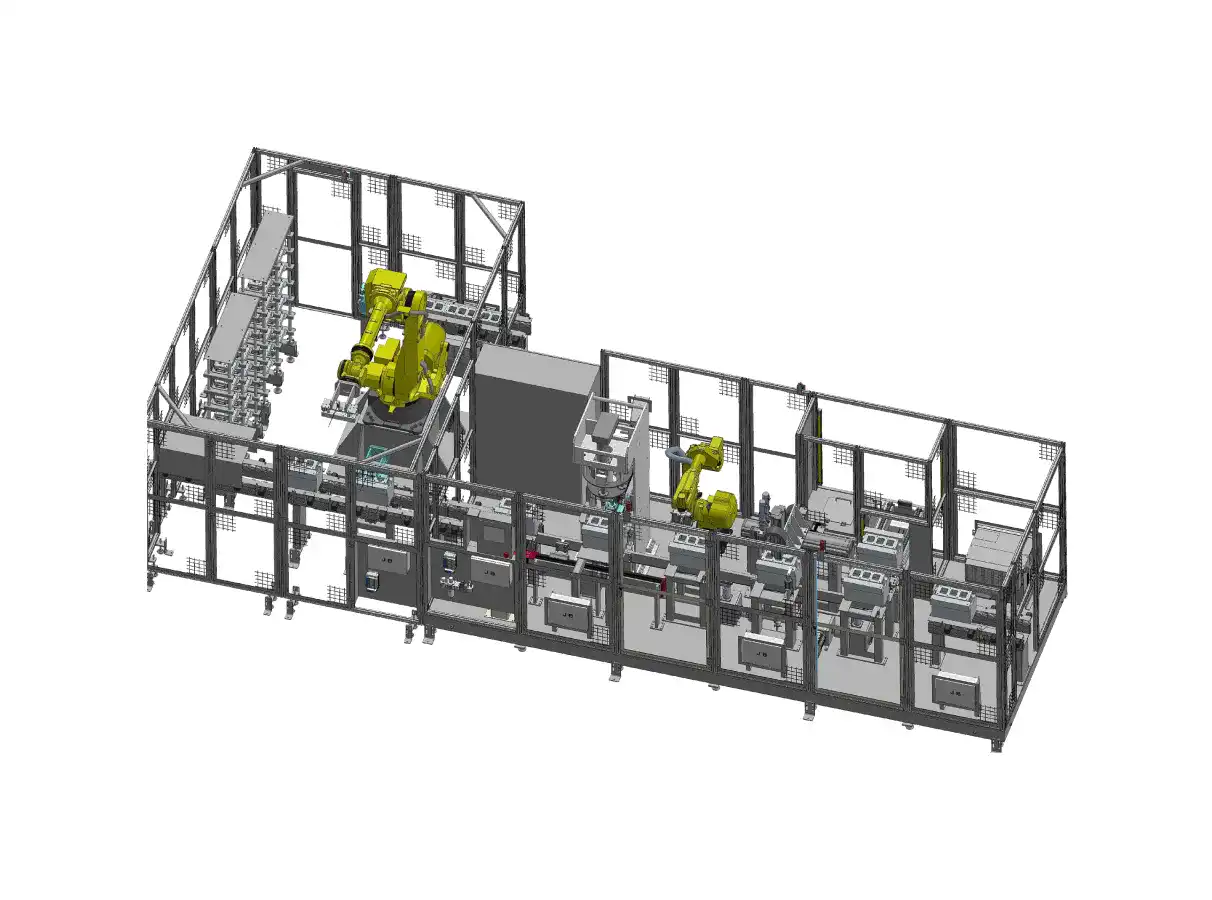

Mechanical Design

With 3D design as our standard, we have more than 20 years of experience in mechanical design, mainly in the automotive parts industry. In cooperation with affiliated design firms, we support mechanical design with 3D simulation. (We use design software such as Solidworks)

- Point

Engineers with over 20 years of experience in designing automation equipment for the manufacturing industry, particularly the automotive industry.

Collaboration with partner firms, support from machine conception to delivery of drawings.

3D simulation supports interference verification and cycle time verification.

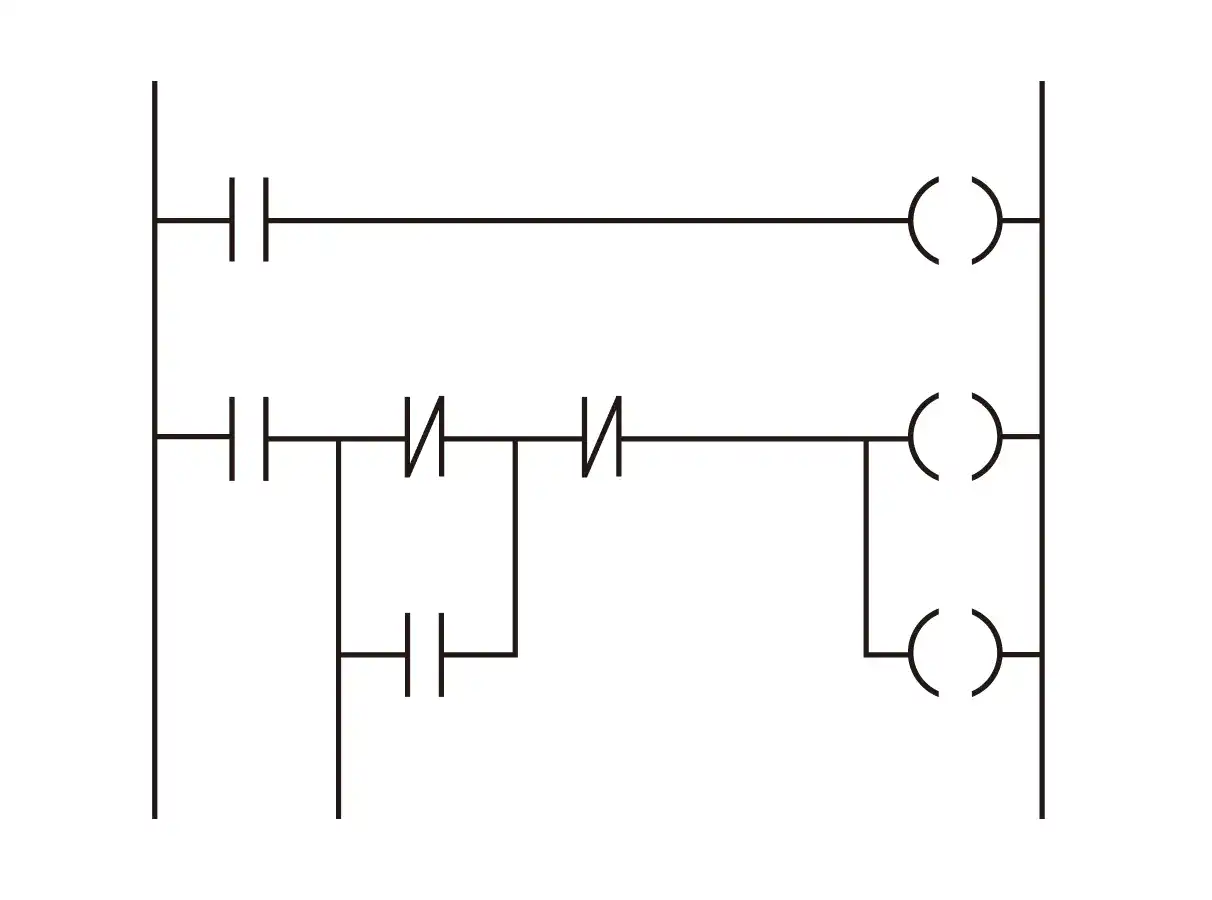

Electrical and control design

Using CAD, our PLC control engineers handle everything from operation panel and control panel design to servo presses and robot systems. We contribute to factory automation (FA) and process automation (PA) that suit your company's production philosophy.

- Point

CAD-based engineers available for PLC control design.

Equipment control support utilizing servo presses and servo motors.

Industrial robot utilization, FA/PA study support.